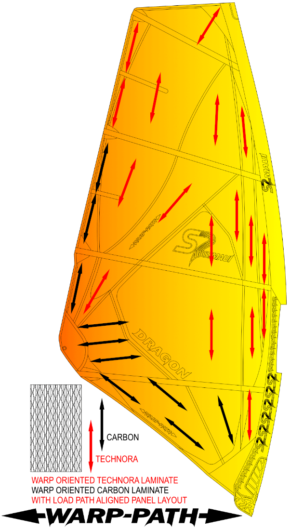

WARP-PATH

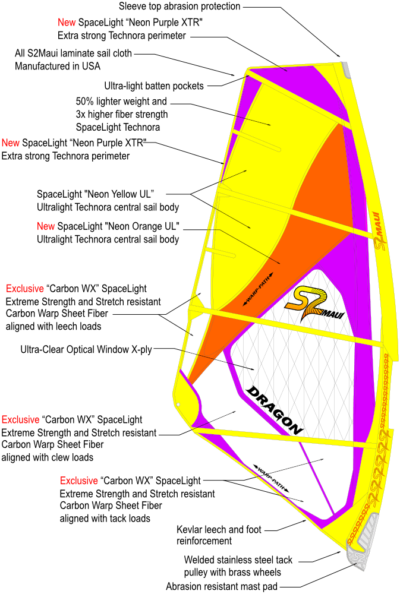

WARP-PATH™, S2 Maui’s functional and unique panel layout, aligns SpaceLight™ warp oriented Carbon and Technora™ fibers along load paths in the sail body.

• LIGHTER SAILS: The strength of load oriented Carbon and Technora™ fibers in super light SpaceLight™ material allows for reduction in patch size which results in a weight of finished sails 10-20% % below industry standard.

• STRONGER SAILS: Load oriented panels with high strength Carbon and Technora™ distribute tension in high stress areas and create an incredibly strong sail body and perimeter. Carbon fibers used in foot, clew and lower leech have 8x higher tensile strength compared to Polyester. Double pass lamination ensures long term durability.

• PERFECT BALANCE AND STABILITY: The WARP-PATH™ engineered panel layout locates each technical material in it’s optimum location to distribute forces throughout the sail body. 10x more stretch resistant Carbon fiber is load-oriented in the high tension tack, clew and lower leech zones, ensuring perfect shape integrity and improving stability and range. Superlight Technora™ fibers are oriented according to twist and perimeter loads throughout the remainder of the sail body, creating a balanced skin tension and a smooth rig response. The rig feels perfectly balanced and connected throughout a wide wind range.

• MORE RESPONSIVE HANDLING: Carbon WX Spacelight™ panels in the tack, clew and lower leech area more directly transmit energy and give the sail an amazing, responsive feeling that has to be experienced. Super-light weight and low stretch SpaceLight™ Technora, oriented along twist and perimeter loads allow for an extremely quick sail twist reflex dynamic. On the water, these technical features result in a magical feel that is light in the hands with smooth consistent power.

S2Maui’s WARP-PATH™ construction also has some notable advantages over expensive membrane sails:

• SHAPING FLEXIBILITY: WARP-PATH™ offers benefits of Carbon and Technora™ fiber orientation combined with the profile control advantages of vertical/horizontal sail shaping techniques.

• CONTINUOUS ONE PIECE LUFF PANEL: WARP-PATH™ maintains a one piece, full length luff panel with Technora™ fibers running the full length of the leading edge, uninterrupted. This is a much stronger construction than typical windsurf membranes, where horizontal seams split the fibers along the leading edge.

• ABILITY TO CONTROL FILM THICKNESS: WARP-PATH™ combines the benefits of Carbon and Technora™ fiber orientation with the ability to also control film thickness where needed for durability. The result is the best combination of lightest weight and also highest strength and durability.